By Neelabh Singh, Partner, Quercus Group

Industrial Symbiosis engages diverse organizations in a network to foster eco-innovation and long-term culture change. Creating and sharing knowledge through the network yields mutually profitable transactions for novel sourcing of required inputs and value-added destinations for non-product outputs, as well as improved business and technical processes.

Although geographic proximity is often associated with industrial symbiosis, it is neither necessary nor sufficient—nor is a singular focus on physical resource exchange. In practice, using industrial symbiosis as an approach to commercial operations – using, recovering and redirecting resources for reuse – results in resources remaining in productive use in the economy for longer. This in turn creates business opportunities, reduces demands on the earth’s resources, and provides a stepping-stone towards creating a circular economy.

The Symbiosis Model — a model for business development in 3 dimensions:

- Economy: Minimizing costs and improved bottom line and competitive edge

- Environment: Resource efficiency through reuse, recycling, and reduced intake of new materials gives high CSR value

- Innovation and development: Improved introduction and access to new technologies and R&D, job creation and regional development

The World’s First Fully Functional Industrial Symbiosis.

Located 110 km (68 miles) west of Denmark’s capital Copenhagen, Kalundborg is a city with a population of 16,343 (1 January 2015) and home to world’s first fully working industrial symbiosis. It’s a leading example of local collaboration where public and private enterprises buy and sell residual products, resulting in mutual economic and environmental benefits. The Kalundborg Symbiosis is an industrial ecosystem, where the residual product of one enterprise is used as a resource by another enterprise, in a closed cycle.

Besides being home to the world’s first working industrial symbiosis, the Kalundborg Municipality is the largest industrial area in the Zealand region, outside of Copenhagen. The municipality is home to a series of ambitious cleantech initiatives including the construction of Europe’s largest demonstration center for biomass refinement, a smart-grid initiative, the 2nd-generation bio-ethanol project Inbicon, Cluster Biofuels Denmark, and much more.

It wasn’t invented, but has developed organically over the course of five decades.

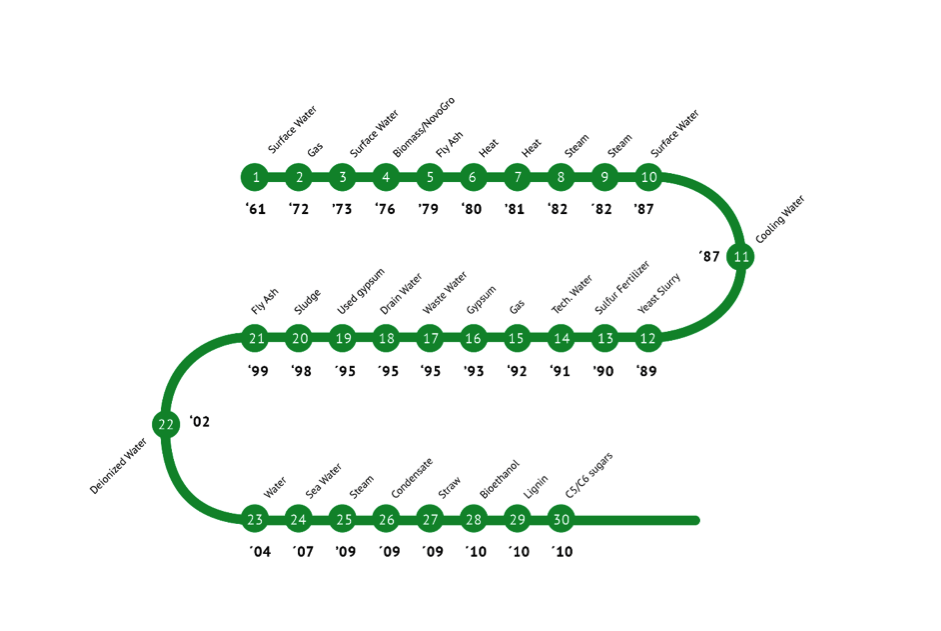

The Kalundborg Symbiosis came into being as a result of private conversations between a few enterprise managers from the Kalundborg region in the ’60s and ’70s. Since then, the industrial symbiosis has developed based on good collaboration between employees of the businesses involved. The continuous development of the Kalundborg Symbiosis has been possible because its benefits have grown yearly, both economically, culturally and environmentally.

The Kalundborg Symbiosis began in 1961, when Statoil (then Esso) needed water for their refinery near Kalundborg. The first conduits pipes in Kalundborg Symbiosis were laid between Statoil and the nearby lake, Tissø.

In 1972, Statoil entered into an agreement with Gyproc, a local gypsum production enterprise, for the supply of excess gas from Statoil’s production to Gyproc. Gyproc used the gas (today, natural gas) for the drying of the produced plasterboard in their ovens.

The following year, 1973, Dong Energy (then, the Asnæs Plant) was connected to the Statoil water pipe, and what would later come to be known as the Kalundborg Symbiosis now had three partners.

Over the years more and more businesses were linked into the Kalundborg Symbiosis, and in 1989 the term ‘industrial symbiosis’ was used to the describe the collaboration for the first time.

The partner in Kalundborg Symbiosis.

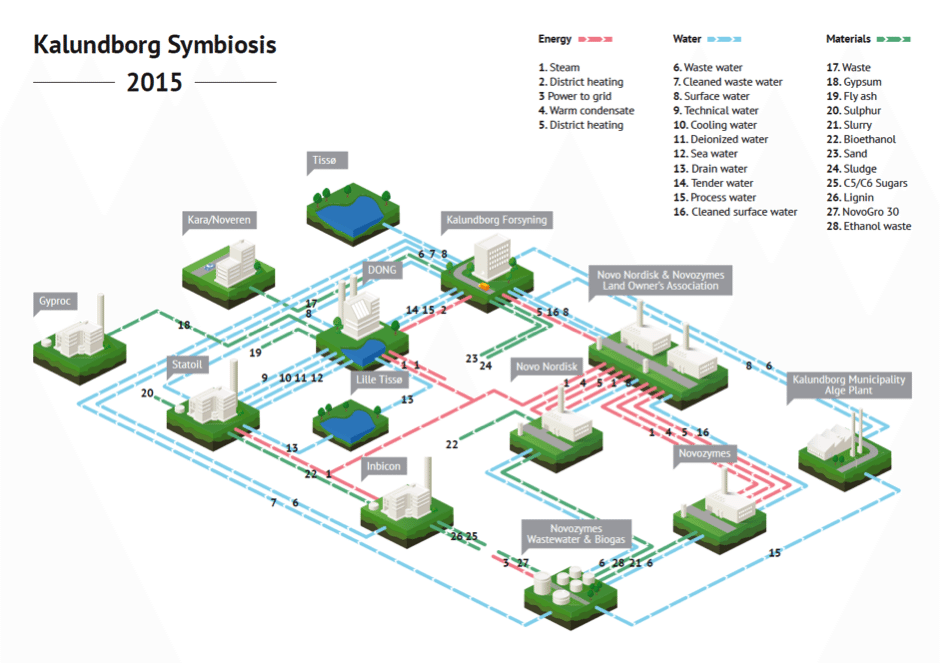

Today, some of the largest industrial enterprises in Denmark are partners in Kalundborg Symbiosis and the symbiosis includes eight public and private enterprises in the Kalundborg area, among which are the world’s largest producer of insulin, the world’s largest enzyme producer, the largest sewage treatment plant in Northern Europe, the largest power plant in Denmark and the largest oil refinery in the Baltic Region.

Systems make it possible, people make it happen.

In the development of the Kalundborg Symbiosis, the most important element has been healthy communication and good cooperation between the participants. The symbiosis has been founded on human relationships, and fruitful collaboration between the employees that have made the development of the symbiosis-system possible. Some of the most important lessons in creating and maintaining successful symbiosis that have been learned over the last five decades are that:

- The members can be different but need to have a commercial fit

- The members focus on large continuous waste streams

- Every project is economically feasible

- The geographical distance between the members is small

- The ideological difference between the members is small

Applying the principles of industrial symbiosis to business practices enables companies to utilise material streams, energy, water and other assets more efficiently, yielding greater overall productivity and adding to the bottom line. Instead of being destroyed, undervalued as a by-product or sent to landfill, industrial symbiosis results in waste streams and other under-utilised resources generated by industrial processes being repurposed for use by an/other companies, typically from different sectors, providing a mutual benefit or symbiosis. Additionally, the approach enables businesses to find reuse outlets for effluents and recoverable energy streams, and can optimise the use of industrial assets, improve logistics, and increase knowledge transfer; creating a demand pull on eco-innovation – in effect increasing the productivity of all available resources generating bottom line and environmental benefits. The following are some examples of resources saved through the Kalundborg Indisutrial symbiosis initiative:

- Ground water: 2.0 mill. m3/year

- Surface water 1.0 mill. m3/year

- Natural gypsum 200.000 tonnes/year

- Oil: 20.000 tonnes/year

- Reduction of CO2 emissions: 275.000 tons

For more information on the Kalundborg symbiosis you can contact the author by writing to neelabh@quercus-group.com

_____________

Neelabh is a Partner at Quercus Group, a niche consultancy advising on green growth and he is responsible for the overall strategy and international business of the firm. Neelabh has been responsible for providing solutions to help ‘Smart Cities’ and ‘Municipalities’ around the world achieve optimum levels of environmental efficiency. He brings together various technologies in the cleantech sector on a common platform and leads the process of co-creating integrated solutions. In doing so he is persistently developing relationships with domestic and international stakeholders and creating innovative platforms for collaboration with foreign cities and regions. Neelabh is currently leading the preparation of a comprehensive report for the Danish Ministry of Foreign Affairs on the Indian Government’s 100 Smart City Mission and the mission’s significance to Danish businesses. In the past he led the commissioning of a unique report that maps globally the trends, opportunities, barriers and key stakeholders of 13 cleantech sectors.